- Office Hours: M-F 8:30 AM - 5:00 PM

A consulting company who used third-party passive cables had ongoing data quality issues after a recent repair. The cables were repaired at the original manufacturer’s factory and passed all quality control tests. The customer requested a rental set of AGI cables from SAGA Geophysics to compare. The AGI rental cables were four years old and heavily used—but passed all of the quality control methods at SAGA Geophysics.

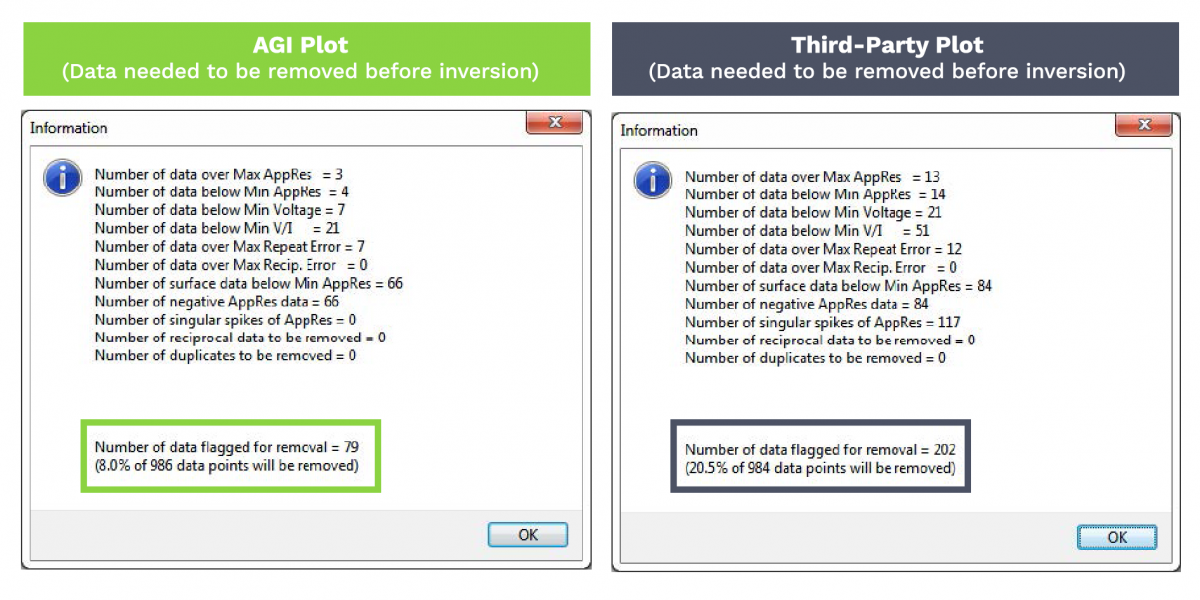

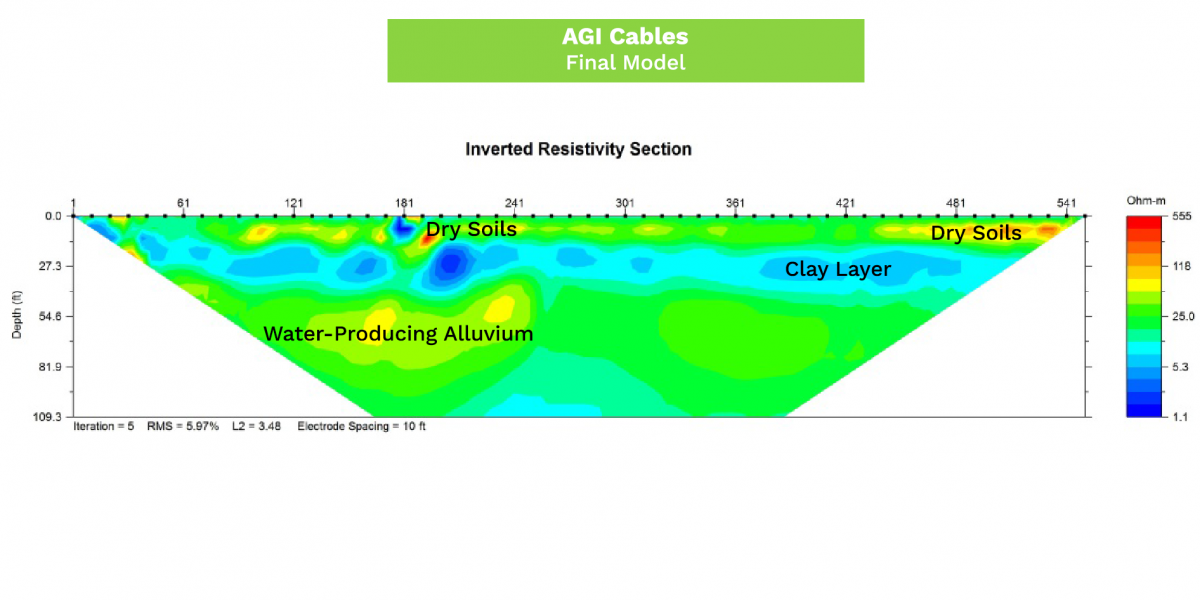

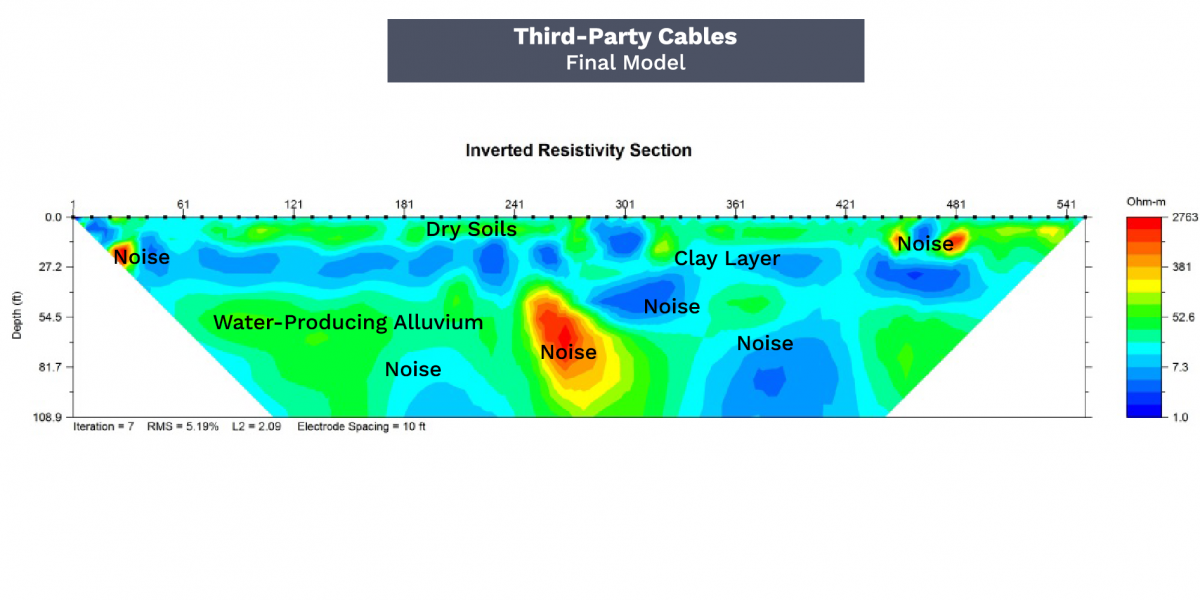

The customer used a SuperSting™ R1 with SwitchBox56™, fully-charged deep-cycle marine battery, stainless-steel stakes, and AGI EarthImager™ 2D software for data inversion. They compared the cables over the same electrode stakes, instrument, command file and contact resistance. All comparison inversion models used the same parameter sets with identical stop criteria and histogram data removal thresholds. Any variations in RMS, L2 or numbers of iterations are related to the amount of noise and spikes.

The customer found that AGI cables measured significantly cleaner raw data with less spikes. Models from the AGI data also converged faster and with lower RMS error and better L2-Norm and contained more good data in the final model. Significantly more data needed to be removed with the Third-Party Passive Cables to fit a good model. The two final models shared similar features, but there were many more clear artifacts in the Third-Party Passive Cables data. The likely cause for the differences in data quality were related to higher electrical leakage or cross-talk noise in the Third-Party Passive Cable.